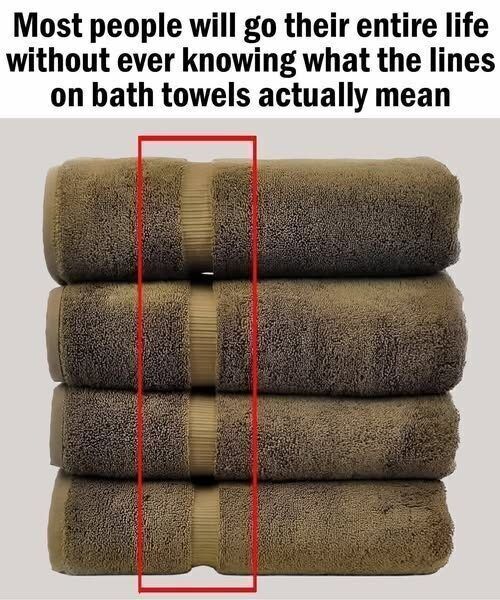

Bath towels often appear simple at first glance, but a closer look reveals design elements that serve purposes beyond aesthetics. One of the most recognizable of these features is the set of raised or indented lines, ridges, or borders near the edges. While many people treat these as merely decorative, they actually reveal a great deal about the way towels are designed, constructed, and expected to perform over time. Understanding the importance of these lines helps consumers make more informed choices, especially because something as ordinary as a towel is used daily yet rarely examined in detail. The discussion of these subtle features opens a window into textile craftsmanship, highlighting how small design choices contribute to functionality, longevity, and user experience. Overall, these border lines are not random embellishments—they are intentional, practical elements with lasting value for durability, organization, aesthetics, and performance.

These border lines, often known in textile terminology as dobby or dobie borders, are created through a distinct weaving technique that differs from the rest of the towel. Whereas the absorbent portion of towels is typically constructed using looped cotton yarn designed for maximum moisture absorption, the border area uses a flatter, tighter weave that sacrifices fluffiness for structure. This difference in weave creates a border that is more resistant to stretching, fraying, and deforming—three common issues that occur when towels are frequently washed, dried, pulled, and folded. The stability provided by this tighter woven edge acts like a frame, helping the towel maintain its shape over a long period of use. It also gives the entire product a clear and finished appearance, enhancing the sense of quality. Through this carefully engineered design, manufacturers ensure that towels remain visually appealing while holding up against repeated handling and cleaning cycles.

The border lines also add functional value when it comes to organization and use, particularly in households or environments where towels must be consistently folded or displayed. Because the lines create a visual division between the edges and the main absorbent field, they serve as natural guides that make folding easier and more uniform. Whether someone is aiming for the crisp, spa-like appearance favored in hotels or simply trying to keep a linen closet tidy, these lines help ensure that towels align neatly and stack evenly. This detail becomes especially useful when multiple towels are kept together, as the defined edges help prevent bunching and irregular folds. Additionally, these border designs can help differentiate one towel from another, which is particularly helpful in shared living spaces or households with several members. Even slight variations in the border pattern can make it easy to keep track of whose towel is whose, reducing confusion and enhancing both organization and hygiene.

Beyond structure and usability, the design of towel borders can also indicate product quality and play a role in determining price. Higher-end towels often feature more complex, decorative dobby borders that demonstrate a manufacturer’s attention to detail and craftsmanship. These patterns may include geometric motifs, flourishes, textured details, or even brand-specific designs that signal prestige. By contrast, lower-priced towels may include only minimal borders or sometimes lack them entirely, relying solely on simple stitching to maintain edge integrity. Consumers browsing for towels may not always consciously analyze these borders, but the intricacy, symmetry, and precision of the weaving often correlate with how much time, effort, and skill went into producing the towel. In some cases, these patterns may be designed to complement bathroom décor or to match coordinated towel sets. In other cases, the inclusion of logos or initials adds a personalized or luxurious touch. Thus, the presence and style of towel lines can serve as a subtle but reliable indicator of overall quality.

Leave a Reply