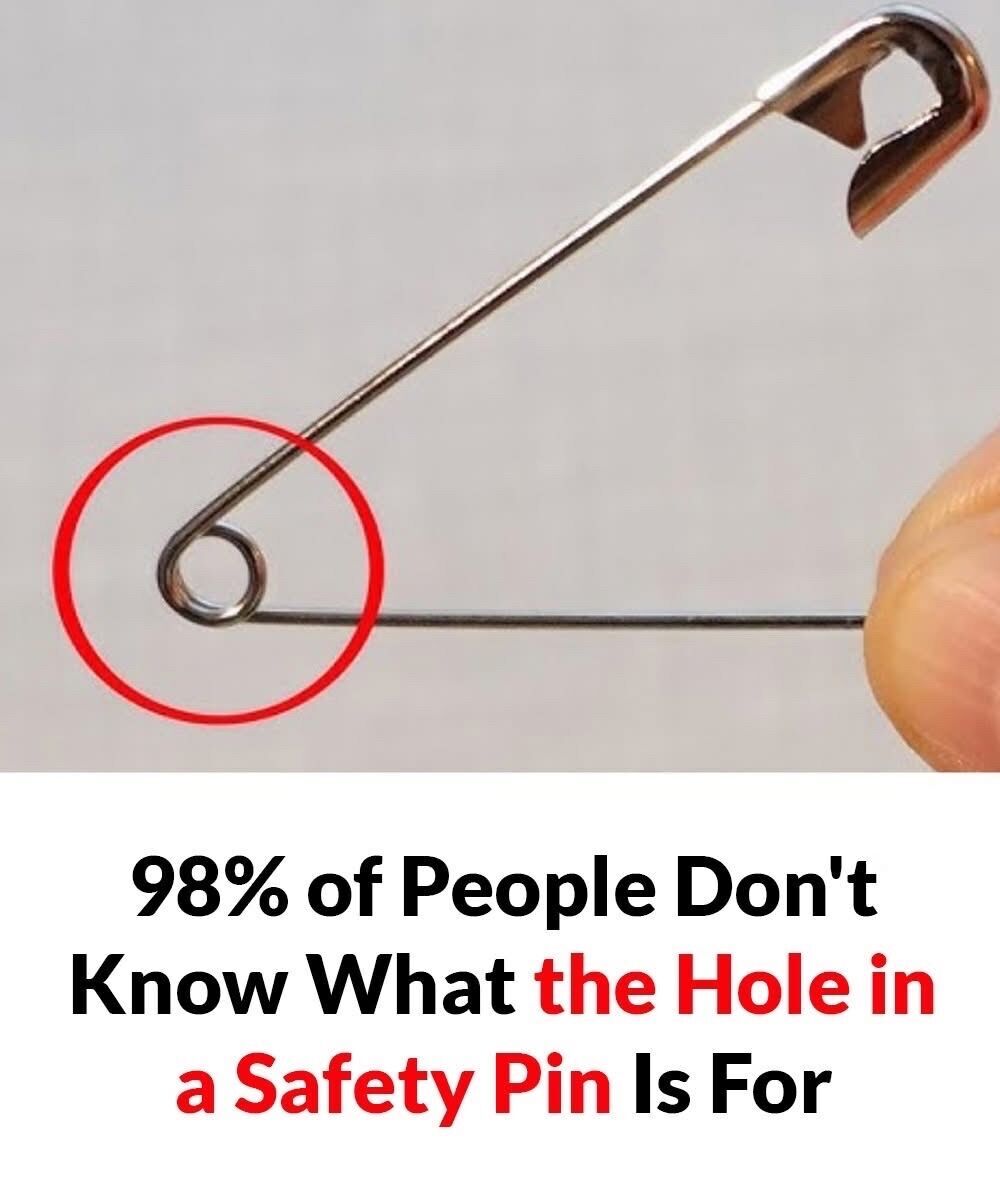

So THAT’S what that tiny hole in a safety pin is for — why didn’t I know this sooner?! At first glance, a safety pin seems almost laughably simple: a small piece of bent metal with a clasp, designed to hold fabric together temporarily and then be forgotten in the bottom of a drawer. Yet hidden within that humble form is a tiny hole that most people never notice, let alone question. It’s the kind of detail your eyes skim over without a second thought, even after decades of use. But like many elements of traditional tools, that small hole is a quiet reminder of how deeply thoughtful early design really was, especially in the world of sewing and textile work. Sewing itself has developed over hundreds of years, evolving from the most basic bone needles and plant fibers into the sophisticated machines and synthetic threads we rely on today. Along that journey, countless practical techniques were refined, perfected, and passed down—only to be slowly forgotten as convenience took priority. The tiny hole in a safety pin belongs to that older world, where every feature had a purpose and every shortcut was born from necessity. In the past, sewists didn’t just use tools; they understood them. They knew how to squeeze maximum function out of even the smallest object, and that knowledge made their work stronger, faster, and more reliable. The hole was never decorative, nor was it a manufacturing accident. It was designed to work hand in hand with thread, cord, or even fine wire, allowing the safety pin to double as a guide, a temporary needle, or a threading aid. In times when tools were scarce and efficiency mattered, this tiny opening transformed a simple fastener into a multifunctional companion, capable of pulling elastic through casings, guiding ribbon through narrow channels, or anchoring thread securely while stitching or marking fabric. Seen through that lens, the safety pin stops being ordinary and starts becoming a symbol of quiet ingenuity, a reminder that the most useful innovations are often the least obvious.

Picture this: you’re sitting at a wooden table, fabric spread out before you, light pouring in through a window. There’s no electric sewing machine humming in the background, no pre-wound bobbins, no automated thread cutters. Instead, there’s patience, practiced hands, and a deep familiarity with tools. In this setting, a safety pin wasn’t just a stopgap for a broken button or a torn hem; it was a vital part of the sewing process. That tiny hole allowed thread to be tied securely so the pin could act as a makeshift needle for thicker materials, or as a pulling tool when elastic needed to be threaded through waistbands and cuffs. Even today, many people instinctively use safety pins for this purpose without realizing that the hole was intentionally placed to make the task easier and more secure. Tie the thread through the hole instead of around the pin, and suddenly the risk of slipping disappears. This same principle applied to marking fabric, temporarily anchoring thread, or even storing small bits of string without tangling. These techniques weren’t written down in manuals; they were learned by watching, by doing, and by being corrected by someone more experienced. Over time, as sewing machines became faster and store-bought clothing replaced handmade garments, much of this practical wisdom faded. We gained speed and convenience, but we lost an intimate understanding of the tools themselves. That loss is why so many modern sewists experience frustration—threads tangling, seams weakening, tools slipping—without realizing that older methods already solved these problems elegantly. The tiny hole in the safety pin is just one example of how much knowledge is hiding in plain sight, waiting to be rediscovered by anyone willing to slow down and look a little closer.

This is where an overlooked technique comes back into focus, one that feels almost magical when you first try it because it solves several problems at once. Imagine strengthening your stitches, reducing thread breakage, and sewing faster—not by buying a new gadget, but by adopting a habit that costs almost nothing. It sounds too good to be true, yet it’s something generations of sewists relied on without question. The method doesn’t involve complicated tools or specialized equipment. Instead, it relies on understanding how materials behave and how simple adjustments can dramatically improve results. Modern sewing often depends on technology to fix issues that are, at their core, physical: friction, tension, and wear. Threads tangle because they twist and catch; seams weaken because fibers rub against each other; stitching slows because resistance builds as the needle passes through fabric. Past generations didn’t have the luxury of replacing tools or materials easily, so they learned to work with what they had. They developed techniques to protect thread, guide it smoothly through fabric, and ensure that every stitch counted. These methods were essential, not optional, because mistakes cost time, material, and sometimes money a family couldn’t spare. Today, when something goes wrong, we’re more likely to blame the thread brand or the machine than our technique. But when you step back and apply some of that old knowledge, the entire process changes. Sewing becomes smoother, quieter, and more satisfying. The frustration fades, replaced by a sense of control and rhythm. It’s no longer about fighting the material but cooperating with it, using small adjustments to create better outcomes. And at the center of this rediscovered wisdom is a natural substance so simple that many people are shocked they’ve never tried it before.

Bringing back a timeless technique doesn’t mean rejecting modern tools; it means enhancing them with knowledge that stood the test of time. While contemporary sewing rooms are filled with high-tech gadgets—automatic threaders, digital stitch selectors, laser guides—past generations relied on clever, low-tech solutions to solve everyday problems. They knew how to keep threads from tangling, how to reinforce seams without bulky knots, and how to mark fabric cleanly without leaving permanent traces. These weren’t tricks; they were fundamentals. One of the reasons these methods disappeared is that they were so effective they became invisible. When something works perfectly, people stop talking about it. Over time, as teaching shifted away from hands-on apprenticeship toward instruction manuals and quick tutorials, the “why” behind techniques was lost. Now, however, there’s a growing movement among sewists, quilters, and crafters to rediscover these old-fashioned skills. Not out of nostalgia, but out of practicality. People are realizing that faster isn’t always better, and that quality often comes from small, thoughtful steps taken before the first stitch is even made. The safety pin’s tiny hole fits neatly into this revival, serving as a reminder that tools were once designed to do more than one job. When paired with other traditional practices, it becomes part of a system that prioritizes durability, efficiency, and ease. These methods don’t slow you down; they streamline the process by preventing problems before they start. In a world where sewing is often treated as either a hobby or a rushed necessity, returning to these fundamentals can feel revolutionary.

The real game-changer, though, is beeswax. This humble, golden substance has been used by sewists for centuries, yet many modern crafters have never touched it. The concept is beautifully simple: before you begin stitching, you glide your thread across a block of beeswax. That’s it. No soaking, no complicated preparation, just a light coating that transforms how the thread behaves. Beeswax strengthens thread by binding loose fibers together, reducing fraying and breakage. It smooths the surface, allowing the thread to glide through fabric with less resistance. It also adds a slight stiffness that makes threading needles easier and stitches more precise. When combined with techniques like securing thread through the hole in a safety pin, the results are remarkable. Seams become cleaner and more consistent. Knots hold better. Tangles become rare. Even hand sewing, which many people find tedious, suddenly feels faster and more controlled. There’s a tactile satisfaction to the process as well—the feel of waxed thread between your fingers, the steady rhythm of needle through cloth, the quiet confidence that comes from knowing your stitches will last. Past generations understood this intimately. Beeswax wasn’t an optional extra; it was a standard part of the sewing kit, often stored alongside needles and pins. It was used not just for sewing, but for leatherwork, bookbinding, and any craft that relied on strong, reliable thread. Over time, synthetic threads and coatings reduced the perceived need for waxing, but they never fully replaced its benefits. Today, as people seek more natural, sustainable approaches to crafting, beeswax is making a well-deserved return, reminding us that sometimes the simplest solutions are the most effective.

In the end, the tiny hole in a safety pin and the use of beeswax tell the same story: nothing in traditional sewing was accidental. Every tool, every material, and every technique evolved through experience, problem-solving, and careful observation. These methods weren’t about doing things the hard way; they were about doing things the smart way with the resources available. When you start to incorporate this old wisdom into your modern sewing routine, something shifts. You begin to see tools differently, not as single-purpose objects but as adaptable companions. You become more attentive to the materials in your hands and more patient with the process. Sewing stops feeling like a battle against tangles and breakage and starts feeling like a collaboration between skill and material. The rediscovery of these techniques isn’t just about better seams or faster stitching; it’s about reconnecting with a craft that has always been rooted in ingenuity and care. The next time you pick up a safety pin, take a moment to notice that tiny hole and remember that it’s there for a reason. The next time you thread a needle, consider reaching for beeswax and giving your thread the same protection generations relied on. In doing so, you’re not just improving your sewing—you’re participating in a quiet revival of knowledge that never should have been forgotten.

Leave a Reply